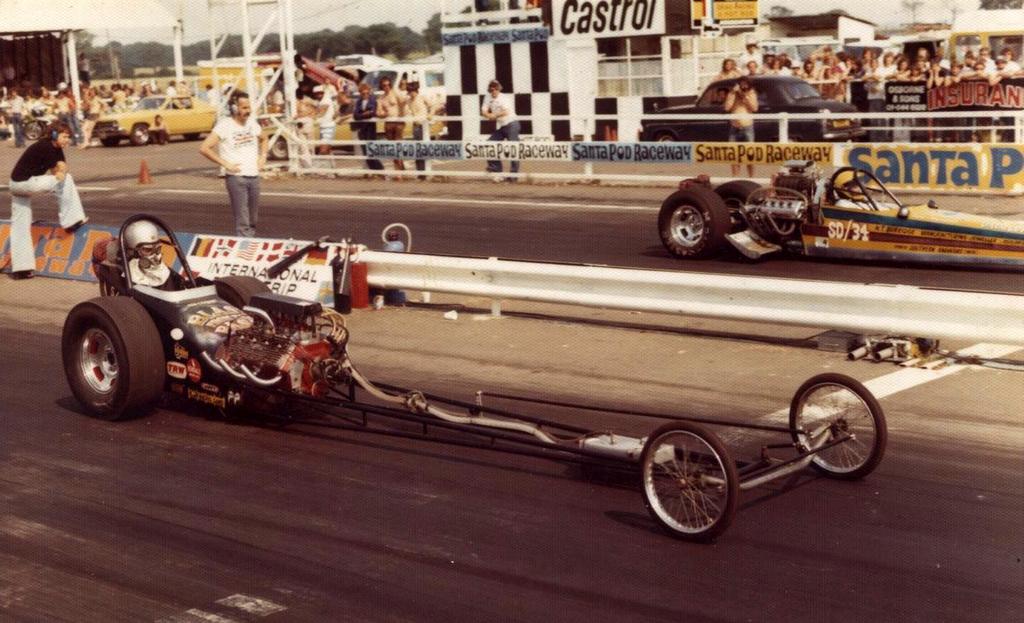

As told exclusively to During the mid to late seventies, Ken continued to work on Blast from the Past, the car getting longer and losing weight, Ken giving some attention to the rear axle and cylinder heads too. Ken raced with the British Flathead Association and even built cars for other racers. After he started a family, Ken kept wrenching the car however Pete Hollingsworth became the driver with Herb Andrews also on the team until Pete got his own car and eventually Blast from the Past was sold. I did a lot with Blast from the Past; I was desperate to save weight so I cut the front of the car off at the firewall and built a new front chassis because it was in the rules you had to run suspension unless the car was 144-inch wheelbase or more and Blast from the Past was a little bit short at 135-inch. I made it 144-inch using some very light tubing and got rid of the torsion bars, suspension and the long radius arms saving a lot of weight. Then went on a purge by putting a lot of holes in the chassis where the scrutineers couldn’t see them and the back of the roll cage where it was covered over with padding. I went to fiberglass panels as well, taking off the aluminium ones and rifle drilling everything. I got it down to 935 lbs which was light in this country. I know Martin Rowatt claimed his Chevy dragster was just down to 1000 lbs and claimed it was the lightest V8 powered car in the country. It wasn’t, it was bullshit, mine was 935, it was in the news letters because Tony Beadle always argued what my car weighed so I took it down to the weighbridge to prove it. I was disappointed as I thought it would be just over 900 lbs. Bearing in mind the Americans were at 820 lbs and Dale got his down to 800 lbs in the end. Mine was 950 lbs when I ran the overdrive and slider clutch which was a light car but it was unsafe. All this work took place after 1974. The thing was I only used 18-gauge tubing for the front of the chassis, I used 16 for the top rails and 18 for the bottom rails. I clipped the exhaust headers down and used different fuel tanks and spindles getting to 945 lbs. It wasn't very safe. I think if I'd crashed it, it would have folded up like a matchstick but it was alright driving it. When you’re a thirty-year-old you don’t think about things like that.

I had an Austin Westminster rear axle and I found some ally finned drums. I think they were Fiat and they were 10 inch the same as the Westminster. I thought if I redrill them for the studs, I bet they go onto that axle. Amazingly they did so I got rid of the heavy cast iron drums fitting the lighter ally finned drums. Then to save more weight when I was running single speed and overdrive. I thought I haven't got the torque multiplication of a transmission so I don’t really need a beefy axle so I used an Austin A60 axle which is really dinky. I cut the ends off the Westminster axle which had all the brake assembly and welded them onto the A60 axle. That took a lot more weight off and I got it down to 820 or 815 lbs. It never broke but the shafts twisted. I had to put some smaller shafts in to go through to the differential. So, I cut the splines off and put a piece of tube over them and welded the tube but the tubes used to twist. Then I swapped them over from side to side and they'd twist back again. But here’s another thing for you. I welded up the spider gear so it’s a locked rear end. Nowadays you use a spool because in the rules you're not allowed to weld them. There’s a fallacy regarding this, if you had a welded one and it breaks the car will slur round because it’s only driving through one wheel. Now I can tell you from experience and I’m not going to lie, I can disprove that. Once I’d locked the rear end up it became very awkward to push round the pits because it won't go on a turn. Even worse was manoeuvring it into the garage, it was a real ball ache. So, after about four meetings, what did I do when I finished racing? I fetched the wheel off, pulled the shaft out and put the wheel back on with three nuts tightened and I could roll it anywhere. Then the next time I took it to Santa Pod. Unloaded it, took it through scrutineering with only three nuts tightened up and two only finger tight. Got back to the pits and without thinking we’d warm the motor up which sounded alright then go make a run. Made the run which seemed alright, got back to the pits and I wanted something out the boot of the car, opened the boot and in an oily rag was the half shaft. Now I’d driven the car with one half shaft with a locked rear end. According to everybody you can't do that, the car will go sideways. I ran the same time a low 11 at 128 mph something like that. My heart leapt when I picked this shaft up out of the boot. I said to Brian look we ran with only one half shaft. I looked around in case anybody could see me, what am I going to do, so I jacked up the car, took the wheel off and put the shaft in. With everybody walking past, what was I going to do, it was awkward, and with only three wheel nuts tightened up. The run was like any other under full throttle, I’m surprised why one wheel didn't smoke. This was still in the 1970’s. I don’t know when this was but Santa Pod stopped pushing starting the cars I think 1978/79.

I’d got ordinary regular Edelbrock standard cylinder heads but fairly high compression ones because in those days they offered three different compression ratios 7 ½, 8 ½, and 9 ½ to 1. I bought these in the 1960s and ran with them for 20 years right up until the 1980’s when I stopped. One day I was thinking about the airflow of the engine as it was quite bad. I had the engine on its stand and thought I’m going to have a pistons eye view. I put a cylinder head on it, turned the engine upside down and shone a torch down the bore so I could see the combustion chamber shape and thought this is a bad shape. This is ever so restrictive; I don’t know why they’ve cast it like this. I’m going to take some metal out of here which is quite daunting, Edelbrock should know more about it than me and am I going to risk grinding metal, I can’t put it back again. When you look down the wall it’s a lot different to an OHV cylinder head and gives you a fresh outlook on the airflow by looking at it from the opposite end. I thought I can improve this, only this is ridiculous. I took the head off and took the plunge and started taking metal out of the chamber which I knew is a double-edged sword. Although it might flow more air, taking metal out will increase the volume and is going to decrease the compression ratio. That’s another sore subject of mine. I cut some of the chamber away and put it back on and next time out running the motor I could feel the difference mainly at the top end it wouldn’t flatten out so much. Whereas before it would reach a certain RPM and stay there, I thought I’m going the right way. So off came the heads again for the next meeting and I carried on taking off more metal and changing the shape of the combustion chamber. At the same time, I’d got some chevy 1.6-inch exhaust valves which were a lot, lot bigger so I cut the seats and fitted them. It ran a hell of a lot better. You felt you could rev it until it came apart where it was like it had a limiter on it before. I didn't have a rev counter in the car because of the magneto which wouldn’t drive a rev counter because the primary circuit in the magneto is AC, all those rev counters run off DC. I’d worked it out with the rear end ratio and having run 132 mph with the car it was 7400 rpm. Allowing for error and all the rest of it, it must have been doing very close to 7000 rpm it wasn’t doing 7400 but it was certainly well passed 6500 rpm very near to 7000 rpm. So, it did really work cutting the chambers away like I did. Fortunately, I did a lot of research. In those days you brought a pair of cylinder heads by the name or what you fancied, I’ll have Offenhauser, Edelbrock but I still look at the chamber shape, I don’t care who it's made by. I’ve got Navarro heads on it now and the combustion chamber is far superior to anybody else’s. In fact, the only one that is better is made by Weiand but they don’t make them anymore, they’re obsolete and you have to find some second-hand ones.

Bradley joins in... With all the work done to the cylinder heads, this was when it came alive and Dad started to run consistent 10 second runs. Although it was one car, there were three versions of Blast from the Past. Ken... Yes, because when I did go to the direct drive and single speed, I realized I didn’t want so much traction, I wanted to spin the wheels. I moved the engine forward quite a bit making a new cowl taking some weight off the back so they would spin. Then when I went back to a transmission, I put the engine back again to where it was. Bradley... There was the first Blast from the Past, then came the lengthened version with the engine moved forward followed by the last alteration of it, the really long car and the engine came back again. Ken... In fact, people said it’s a Garlits car, it looks like Swamp Rat 13. I was a huge Garlits fan and that's why I always had my car black. I’d moved to this house which really helped because I had my own bigger garage and could do a lot more as I got more enthusiastic, confident and adventures and started to develop things. The modifications took place during the mid 70s, the Silverstone era, we attended quite a few meetings there. Bradley... It was a very uncomfortable car to sit in and drive. Anyone who sat in it said it was terrible to sit in. Ken... At the end of the season, I let Brian Gleadow drive it at the last meeting. He’d worked so hard with me all year and he said it was uncomfortable. Mike Gleadow had sat in as well and said the same. I only had an aluminium seat with no upholstery. Why did you need it, you only sat in it for a while and I wanted to keep the weight down. Another thing I did was I made it an 8-port motor because the Flathead is only a 6-port, three exhausts each side. The two middle cylinders have to exhaust the same pipe. You could bore through the block and manifold and put in another pipe at the top and curl it out. It was a lot of work but I did it. I didn’t detect any more in the performance afterwards. But it seemed to run a lot cooler. In the last version of Blast from the Past I changed transmissions to a GM automatic with a clutch, I had a Harry Weber 10-inch clutch from the States. Then Pete Hollingsworth started to drive my car.

Bradley... Dad promised Mum that when they have a family he'll stop racing, but when I was born in 1978, Dad didn’t. Then toward the end of 1979 my brother Mitchell came along and it was like then you’ve got to stop racing. So that's when Pete Hollingsworth drove for about two seasons, while Dad continued to wrench on it. Pete ran 10.70 straight of the trailer. Any photos of Blast from the Past where the driver has a green helmet is Pete. Pete lived just up the road from Dad and when Dad went yachting with us Pete would come here to collect the car then go racing and would still keep collecting the points. Herb Andrews was a mate of Petes and would crew for him. Pete then wanted his own car. Ken... After Pete got his own car, my dragster languished in the garage for about four or five years. Bradley... As a very small kid, I can remember seeing it in the garage and the local group of about 20 Scouts would come round to look at it. Ken... In 1985 somebody phoned me out of the blue, I understand you’ve got a dragster in your garage, yeh, yeh, yeh... is it for sale? I said it isn’t exactly for sale but it can be bought. He came and had a look at the car, the trailer and all the spares. We did a deal; it was Dave Hartshorne from Derby. He’d turned up with a 1957 Chevy 2 door and trailer, hooked the whole shebang up and took it away. He raced it with the Flathead for a very short time. He asked what rear end was in it, I said a 3.9 and he said that’s no good, it want’s something like a 4.23 blah, blah, blah... I said it might if it’s got a high winding Chevy up front but believe me after 20 years, I know what’s best for a Flathead. He disagreed saying that’s a bit tall and within weeks he’d blown the motor out of the chassis and it ended up with a Chevy in it. I’d run that Flathead for over 20 years, one of the oldest motors running. In that time, I’d only melted a few pistons. This guy Dave also cut the front end off and made it much longer. He emigrated to Canada and then Martin Canto brought it from him. Martin didn’t run it for long. He was coming down the return road being pushed back and the chassis broke off where Dave had lengthened it. This must have been 1989/90 or the early 1990’s. I started my model airplanes again at this time. Martin put a new front end on the dragster but then had a heart attack and couldn’t get his race license and from that day on we just don’t know where the car ended up. The car I had out the back in the garden was the BB&G car which is technically the brother car to Bazooka Too. It was virtually a replica of that but slightly longer and wider because the bloke I built it for was a big lad. I also built the 4th Dimension car for Andy Swaffield. We’ve had a lot of people contact us saying they’ve found my car and they send me a photo of it but it turns out not to be. We spent a year trying to find it, but if we do find it, it will need a lot of work done on it to meet the current rules.

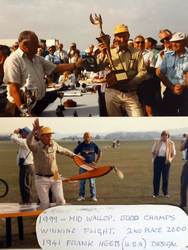

I won some championships and have a collection of trophies. Andy Swaffield’s brother who was a stonemason carved out of wood a lovely shield which I mostly designed for the winners of the British Flathead Racers Association championship. I said to him why don’t you put on a cylinder wall with 2 valves and he carved a Flathead cylinder that was full size on the shield making a lovely job of it. I don’t know who’s got it now.

British Flathead Racing Association Newsletters and Ken's recording of a Flathead (content opens in separate tab) Ken takes his cassette recorder for a run

Gallery: click on any thumbnail for a large image.

Back to pioneers index Back to News page |