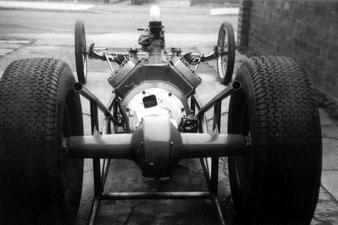

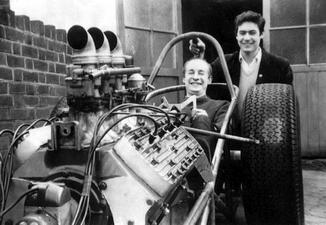

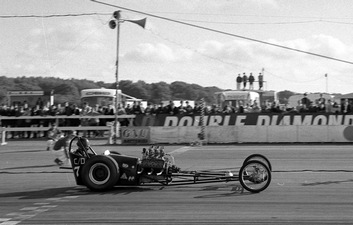

As told exclusively to Ken built Bazooka Too, a more modern design, in 1967 which he ran until 1972 when he built Blast from the Past. With parts from Tony Beadle, Ken bored the engine out to 286ci and ran it on methanol with four Stromberg carbs and a full race cam. He then went direct drive with a slider clutch and ran 50% nitro, following which he experimented with different gearbox configurations and different fuels including hydrogen peroxide (not for long). In building a spare engine, Ken ground his own camshaft to the amazement of the competition - and knocked 3 seconds off the ET of the spare motor! By 1966 the dragster which I’d started to put together in 1960 was five years out of date. Dragster design had changed a lot in those five years so I decided to build another for 1967 which didn’t take long. It was basically just another chassis. I was using the same drive line and engine. I built a better front axle and all the rest of it. It was a lighter car and more of the trend. I can't think of any milestones really apart from I was the first bloke to 100mph in the dark at Santa Pod in 1967 against Alan Blount I think it was. I called it Bazooka Too and ran it until early 1972. I built another car when I moved to where I live now and had a bigger workshop. This was Blast from the Past, a very light car which I debuted in 1972. The Bazooka Too chassis still existed for quite some time and ended up with a Humber 6-cylinder engine in it, painted white, run by John Martin who called it Piston Broke.

Somewhere around 1968/69, Tony Beadle started a little side line importing parts from America, calling it Speed & Custom Parts. He said you ought to bore that motor bigger, it won't half go. He said I’ll get you some 3⅜ pistons and a 4-inch crankshaft, you can make a big motor out of that. So, I agreed and he got some Jahns Pistons, so I could bore the block 3/16 making it a 286 inch motor. I’ve still got one burnt piston here still. That big motor went into Blast from the Past. I used the same engine block in the original Bazooka at 244 inch and ran it until I stopped racing. In fact, the same engine just got bigger and bigger in its capacity.

Right from the word go I ran alcohol so I had to modify and rebuild all the carburettors to run on alcohol. Not just change the main jets as a lot of people thought and the job was done, not so. I ran the 3-carb manifold with the Holley 94’s for quite some time. Eventually I got pissed off with them because they were so awkward and I switched to Stromberg 97’s. At that time, I’d met an American serviceman who was stationed over at Upper Heyford, a lot of them used to come to Santa Pod. I got friendly with this one guy Dale Vaznaian. Dale and his partner started Nitrous Oxide systems. When he went back to the States, we corresponded a lot and wrote to each other. He hadn’t been back to the States that long and he’d got himself a Flathead Dragster with a 4-carb Edelbrock manifold. Later going to fuel injection I can’t be bothered with the carbs he said. This was a surprise because he was always taking the mickey out of me saying I hadn’t moved with the times. Why haven't you got overhead valves? Why have you got an antique? So, he offered me the 4-carb Edelbrock manifold which went on Blast from the Past. Clive Skilton had gone over to get some parts and he collected it for me. Back then I thought it was the greatest thing since sliced bread but I’ve since learnt it’s not.

I had a ¾ race camshaft that came out of a stock car but I wanted a full race camshaft for drag racing, something really good and Tony got me a Potvin Eliminator camshaft. He phoned me up and said I’ve got your camshaft; d’you want to see it? I wouldn't put it in my engine. Why what’s up with it? you want to see the shape of the lobes. When I saw it, I could understand what he was talking about. The lobes were like chisel points. On the box it said this camshaft will eliminate the competition or the engine! Once installed it actually worked really well. The only thing that happened to it was I chipped a lobe when a valve touched the head. That’s when Allan Herridge welded it for me and I never looked back. The engine remained substantially the same and went into Blast from the Past. I started with a Ford Flathead gearbox with reverse and first gears removed, I’d just got two speeds but they never lasted five minutes. They just kept stripping the teeth. Allan said you want them heat treated. I knew in the States a lot of them softened them because they hardened like glass and lasted for thousands of miles but were too brittle. By heat treating them it would soften them. It didn't matter about the wear as long as they weren't so brittle. Allan heat treated them for me and they didn’t last two runs. They were worse than the stock gears, no fault of Allan. And in his cockney accent he said you're making too much f-----g power, you'll have to get suming else. I honestly can't think what I used next. I think I must have dispensed with the gearbox and run direct drive as a lot of the American cars did. But of course, I missed the trick, the Americans all ran 80% Nitro, they’d got the power to pull direct drive. When I was conversing with Dale, he told me he’d got direct drive and was running in the 9’s at 140 mph. I said I can't believe your running direct drive with a Flathead especially with an Oldsmobile axle. Believe me he said it pulls it easy but the trouble is a small percentage of nitro is no good you've got to go to 85%, it’s no good putting in 30-40% it makes no difference. I didn’t, I had about 50% and it did work with the direct drive but wouldn’t run any quicker and was still running low 11s. It wasn’t breaking anything and was reliable but it was getting expensive to run at 50% all the time. About the same time slider clutches came on the market. That was the way in America and they all started to use slider clutches instead of spinning the tyres. I thought yeh there’s something in that you know, so I made myself a slider clutch. I’d got a full race clutch pressure plate with a manganese steel shoe inside it so it wouldn’t explode and it would take the heat. There were nine springs, I took them all out except three, put in three soft springs and had about 700 lbs static pressure on it. Which was enough to turn the engine over and start it when you pushed it. Then I got a metallic disc, luckily all the blown Chryslers like Skilton and Priddle, had the same spline as the early Ford. Clive Skilton used to get about six runs then scrap them because they were too thin. So, Don Beadle who was crewing for Clive used to get the sintered disc for me and there was probably another 15 runs left on it. I could use a centred iron plate and I could slip it. I changed release arms and put bob weights on it which was a lot better but it was having to mess with the adjustments all the time. After two or three runs you've got to adjust it somehow, put more base pressure on it or change the bob weights. Too much of a hassle really.

I would like to mention night racing in a bit more detail. It was the late 60s I guess; the RAC decided they wanted a safety demo. So, after a normal meet, volunteers were invited to run in the dark in like a run-what-ya-brung, provided you had a rear light, i.e. a red cycle light! It's now dark and damp, I pull up to the start line, can’t see much through misty goggles, I bring up the rpm’s, green light and I dump the clutch. Instantly the cockpit lights up yellow and sparks fly between my legs. I'm waiting for a bang! Then I suddenly realise it’s only clutch dust, not visible in daylight, coming from the sintered iron disc slider clutch. I made a few more runs and as mentioned earlier, did the first 100mph night-time run. The next trick was overdrive, Russ Carpenter was one of the first. We thought we want a lower axle ratio running single speed really to get off the line but then it over revs, so how about an overdrive and a clutch-less shift. When you’ve got a slider clutch you can’t use a transmission because it won't disengage once the motors revving and the weights fling out it’s almost solid. So, it’s got to be a clutch-less shift. But the overdrive was only about 12% so that meant I could only lower the axle ratio by the same amount. You really want a crown wheel and pinion about 5 to 1 and shift it up to about 4 to1 but the overdrives were always about 12%. They worked reasonably well but you still couldn’t have a low enough axle ratio to get a good launch. They were pretty bulletproof; I never broke one and ran that for a while. Then we moved to an automatic. After that I thought I’ll go back to a stronger manual transmission. I used a Zephyr six. Now the Zephyr six had a 4-speed box and the ratios were quite favourable. The trouble with the Flathead gearboxes, they were very coarse gears so they only have one tooth engaging in two, that’s why they tended to break. With the Zephyr gearbox there are fine teeth and there’s three teeth engaging four so although they were smaller teeth, they were stronger because you’d got more of them. That was the trouble with the American boxes, 3-speed big coarse gears. The Zephyr box was an H pattern shift so I worked out a way I could convert it into a straight-line shift. Click, click, click but you could only do it once then you had to reset it. I used what they called a firing pin, a spring-loaded pin that would move it over for you. I primed it with the pin and you could pull the lever back and it would shift three times. I had another stop to reverse. To make a run again you’d have to pull the pin out, push the lever forward and push the pin in again. I then converted the 4-speed box to a 3-speed straight line shift. People were quite intrigued by it, that you had to set this pin. I think I’ve still got that shifter in the garage.

In the meantime, and because of the cost of Nitromethane, I thought perhaps I’ll find an alternative to it because basically it’s an oxidiser like Potassium Manganate or Hydrogen Peroxide. So, I thought I’ll try Potassium Manganate but that was a bit of a failure because it dissolved in the fuel. What I didn’t realize was that once it went through the carburettors it was trying to atomise in the venturi, it would fall out of suspension and go back to a crystal. This would happen after a short time of running so the carburettors used to foul up if you were kept waiting on the start line. Next, I tried Hydrogen Peroxide but it was getting hold of it. You could buy it from the chemist because it was used to bleach women's hair but it only came in 30,40 or 50 volumes. It was dissolved in water so there was a limit to how much you could put into the fuel system because you're putting water in it. Then Gerald Cookson came to the rescue. Where he worked at Lucas in the drawing office, they’d got a laboratory. He said I’ve had a word with the blokes in the lab. They've got pure Hydrogen Peroxide. I could get you some but it’s very dangerous and it will burn you. After a bit he did come up with some neat Hydrogen Peroxide and said I think I’m going to try some of this, it sounds very interesting. But there was a problem with that as well. As soon as you added it to the methanol in the tank and put the lid on, it started to fizz and build up pressure in the tank. The fuel used to go up the fuel line very quickly and you’d have to take the top off quickly so it went back to the tank. It didn’t seem to make much difference to the engine anyway. But I know it has been used. In fact, the Germans used it in that rocket plane with methanol but it was very dangerous because if you’d left a bit in the tank and landed the vibration would make it explode. Sammy Miller used in Vanishing Point, his Rocket car and I believe he could only get it from NASA under license as it was so dangerous. But Gerald Cookson and the blokes in the lab got it, don’t forget this was the 1970’s, it was all a bit easier then.

But then I went back to Nitromethane and burnt a piston putting me out of action for a few weeks. I was doing very well in the points chase in the British Flathead Racers Association at the time and if I didn’t run the next two or three meetings I’m was going to be eclipsed. I decided to build up a junk motor and if I only ran 14 seconds or so I’d still get some points and keep my lead in the championship. So, I got an old block. It was a bit of an oil burner and the piston and rings were bad. I put it in the car, fired it up and it blew a lot of smoke out, I thought oh blimey and how embarrassing. I took it to Santa Pod with this gash motor. It had odd pistons in and everything. I know me and Brian Gleadow took the manifold off and put rags in the manifold to try and stop some of the blow-by in the crankcase which kept some of the smoke out. Then we took the manifold off again and put a piece of cardboard on top of the rag. It was turning out 14 second runs but I was picking up points. I thought the trouble with this was that it only had a stock camshaft in it and I didn't want to put my Potvin camshaft in it because that cost a lot of money. I didn’t want to bugger it up in a junk motor. So, I thought I’ll grind my own camshaft which I did in the garage here. I thought how I am going to grind my own camshaft? how am I going to feed it into a grinding wheel and degree it off and all the rest of it? I spent about a week working out how I was going to make a jig to do it and ended up with a piece of tube and two A35 con rods which fitted and clamped onto the tube. Where the gudgeon pins went, I put two pins where I could put the camshaft on. Then by turning the tube I could feed the camshaft onto a grinding wheel. On the end of it I had an aluminium disc which I degreed off to how many degrees I wanted so I knew how much I was turning. Then I put a stop on the other end with a clamp and made it so it would slide along. I wanted a better grind stone and a pal of mine who worked in a company with abrasives and diamond wheels got me a nice wide grinding wheel and I’ve still got it. So, I got this stock camshaft and degreed it all off. I was ever so ambitious and I thought I’ll have more duration on the exhaust lobes because the Flathead is quite congestive on exhaust having to go through the block. So I ground the inlets to about 280 degrees opening and 290 on the exhausts and more lift of course. It took me just over a week doing 2 or 3 lobes a night after I’d finished work. The last little bit I finished with a file just to blend the flank in with the camshaft only the grinding had left a slight lip. I put it in the motor and turned it over to check if the valves were opening, it didn't seem far out, and took it to Santa Pod. Brian Gleadow was crewing for me at the time because he hadn’t got a car. We put it on the rollers, fired it and it ran straight away and thought that’s a relief it’s going. Still blowing out blue smoke as it was a tired old engine. We called it a Risky Cam. Derek Benbow was there and he said, you haven't ground that camshaft yourself, have you? yes, I have. Well, how have you done that? You know the car went from running 14 seconds to 11.33, we were amazed! It was almost as fast as I was going with the Potvin. My best was 10.68 at 132 mph with the Potvin. This was all with Blast from the Past. It was 1974 as I’d ridden out the year on the burnt piston. I can't remember if I won the championship or not but I’d have to say without any sense of false modesty find me another drag racer in that era who ground his own camshaft. Martin Canto had a Flathead Dragster prior to his Top Methanol Dragster. I said you can have my old Risky Camshaft. Then years later I asked him what his best time was with the dragster, he said 11.40 so it was still working well. Ken's Cine Film and Photos Gallery: click on any thumbnail for a large image.

Back to pioneers index Back to News page |